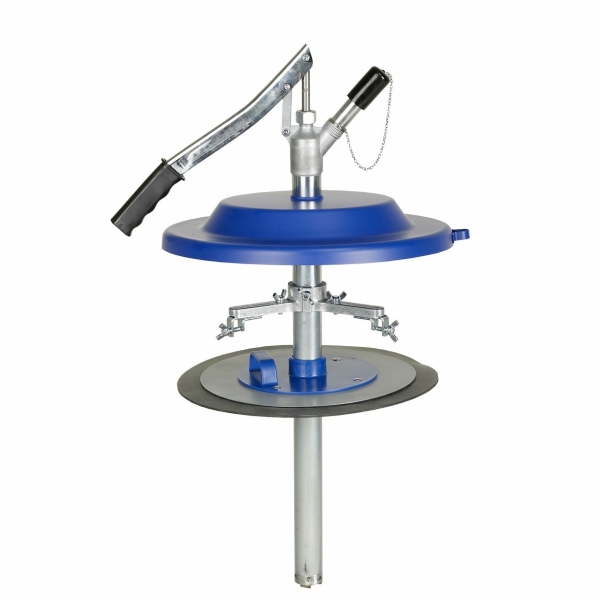

Hand Grease Pump PRELIxx PRO Red

Hand Grease Pump PRELIxx PRO Red

PRELIxx PRO 2014.1 M 10 x 1 Item number: 14 200 331

Technical data

Grease gun connection, pressure-side: M 10 x 1 Filling nipple and ventilating valve: M 10 x 1 Capacity (cm³): 500 Refilling options: 400 g grease cartridge, DIN 1284, grease filling system or loose grease using a spatula Diameter of grease piston (mm): 9 Grease pump piston actuation: manually lever operated Delivery rate/stroke (cm³): 1,2 at a grease density of 0.92 kg/dm³, tested with grease cartridge 400 g (12 511) Discharge pressure up to (bar): 600 Burst pressure system (bar): 900 Burst pressure grease gun head (bar): 1200 Operation of push rod: with T-grip Cover: loose Wall thickness of grease gun tube (mm): 1 Grease gun tube colour: Red

Dimensions LxWxH (mm): 395 x 140 x 66 Weight (kg): 1,35

Specification

● With hose bracket ● Separate filling and ventilation valves on grease gun head ● Filling nipple (FN), M 10 x 1 male (12 670) ● Venting valve (ETV), M 10 x 1 a (85 277) ● Galvanized parts: hand lever, push rod handle, locking catch, head ● Grease gun head, zinc die casting Z 410 ● Ball seat valve, galvanized (85 589) ● Dismantleable and movable push rod system ● T-grip, optimized grip and pressure optimized ● Ergonomic handle, non-slip, excellent power transfer and handling ● Grease gun also available in the colors silver, red, blue, green and yellow Special notes ● Operates with greases NLGI grade 3 at 20°C ● Quantity of delivered grease at a back-pressure of 200 bar nearly unchanged after 40,000 operating cycles ● Pump piston, cylinder and O-ring with 6 μ fit (no dummy lubrication) ● At high back pressure, e.g. gummy lubrication point, lubrication can be achieved with significantly less effort by shorter strokes ● Grease supply variable from 0,1 to 1,6 cm³ per stroke ● Thanks to the optimized hand lever kinematics, lubrication can be done with little effort ● Plunger with exactly fitting when using bulk grease or cartridge ● Due to the flexibility of the push rod, the plunger can be inserted into damaged cartridges or cartridges not exactly matching the standard dimensions ● Damaged cartridges can easily be removed ● Push rod can be locked in any position - push rod does not have to be fully retracted to release the spring pressure on the grease (grease does not saponify) ● The ease of dismantling permits simple cleaning ● Rolled thread on the grease gun tube resists damage from impact and allows quick and easy screwing-in by 1,5 turns ● High-speed ventilation, by half a rotation of the grease gun tube ● Designed for use in rough conditions