Lubrication Equipment Parts and Accessories

PRODUCT CATEGORIES

- Spill Trays, Drum & IBC Spill Pallets

- Waste Spill Trays Drum Spill Pallets IBC Spill Pallets Drum Trolleys & Dollies Hard Covered Spill Pallets About International Waste Management Law

- Grease Pumps

- Pneumatic Grease Pumps Grease Supply System , Mobile Mechanical Grease Pumps Lubrication Equipment Parts and Accessories Electrically Operated Grease Pumps Grease Nippels

- Oil and Chemical Pumps

- Pneumatic Pumps For Oil (Valvolin’s) Oil Supply System , Mobile Electric Operated Drum Pumps Drum Hand Pumps Mechanical Thin Oil Pumps (Valvolin’s) Electric Operated Oil Pumps Waste Oil Drainer Trolley Range Air Operated Waste Oil Drainers

- Oil, Grease and Diesel Meters

- Dijital Oil and Grease Flow Meters Diesel and Oil Manual Flow Meters

- Automatic Reels

- Hose Reel Automatic Open Hose Reel Automatic Locked Air Water Hose Reels Cable Reels Manual Hose Reels

- Fuel Transfer Equipment

- Diesel Transfer Pumps and Systems Nozzle Valves

- Funnels, Measuring jugs, measuring cans

- Measurings Funnels

- Garage Equipments

- Pressol AdBlue Transfer Systems ( Urea) Lubrication Truck Stations

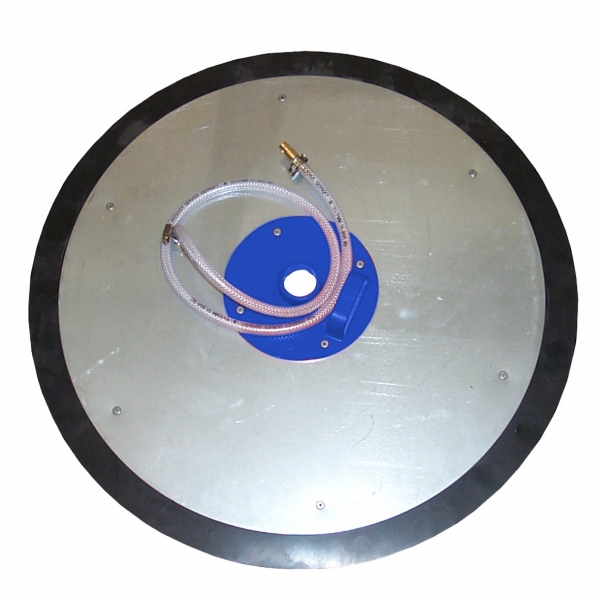

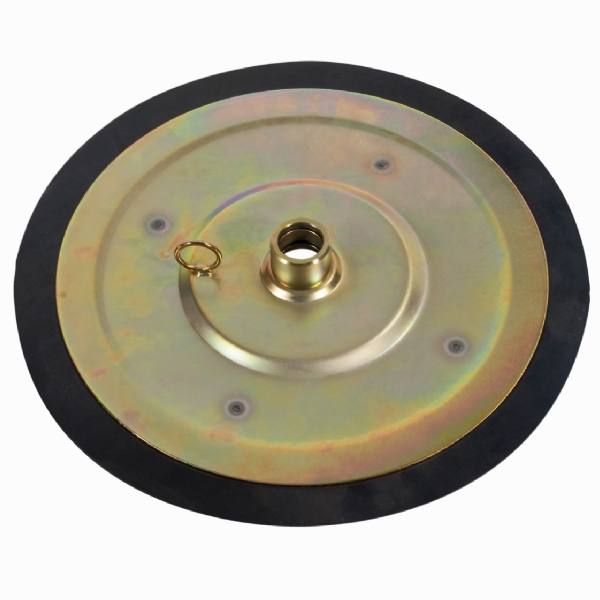

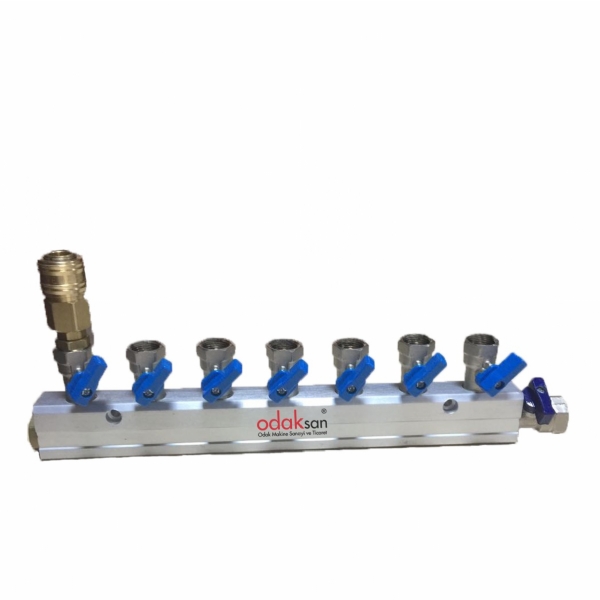

In order to meet all the lubricants, in your factory, workshop and other facilities, sometimes a fixed lubrication system or barrel type air grease lubrication systems may not be able to meet your needs. The area to be lubricated may not be within easy reach. You may have difficulty carrying it. Air Grease and Oil Pumps, produced with superior German technology, provide you with the opportunity to move and intervene in a wide area with their high performance, silent operation, endless spare parts assurance and mobile portable qualities. All the accessories you may need are available on the lubrication system, and you only have to supplement your grease and drive it until the area where you will lubricate. Lubrication equipment, Grease lubrication manual and air operated grease pumps are designed to discharge standard 18, 50 or 180 kg (39, 110 or 400 lb) grease drum LAGG series full range pumps. Can be connected directly at suitable lubrication points, also for central lubrication grease systems. Easy to install and ready to use pumps Consist of units available for 18, 50 or 180 kg grease drums High pressure; 50:1 (400 Bar) maximum, easy installation, reliable; grease guns tested and approved for pressol lubricating greases grease guns; Ideal for the agricultural, industrial and construction industries and for private use. Flexible 300 mm grease hose can also be used. Lubrication pumps etc & so on, Grease Pumps, Pneumatic Pumps, Electric pumps etc. However, the most popular are grease pumps, manual pumps and pneumatic grease pumps. Air Grease Pumps are the most widely used pumps in the industrial world. These pumps provide an easy and convenient option for lubrication. The oil pump is intended to distribute oil as a lubricant to machinery application parts. The grease pump is quite convenient and provides trouble-free feeding for machines consisting of 1-20 lubrication points.