Pressol Pneumatic Grease Pump 15:1 1000 mm

Pressol Pneumatic Grease Pump 15:1 1000 mm

SRL 1000, 200 kg container

Technical data

Length suction tube (mm): 1000

Pressure ratio: 15:1

Max. diameter (mm): 130

Max. air pressure (bar): 10

Min. air pressure (bar): 2

Recommended air pressure (bar):8

Cylinder capacity engine cm³: 220

Quantity of strokes at 8 bar at a

free-flow (min.): 220

Cylinder capacity pump cm³: 13

Pump capacity at 8 bar at a

free-flow (g/min): 1700

Pump pressure at 8 bar air

pressure (bar): 120

Air consumption at 8 bar air

pressure (l/min): 400

Length of discharge pipe work: Depends on size of installation.

Max. suction heigth: The pump ist constructed to be operated directly at the point of suction

Compressed air connection: G 1/4″ female

Grease connection, suction side (ø mm): 35

Grease connection, pressure side: G 1/4″ male

Noise level idle running acc. to

ISO 9614-2 at a distance of 2 m (db A): 78

Noise level under load acc. to ISO 9614-2 at a distance of 2 m (db A): 77

Viscosity of discharged liquid: grease up to NLGI 3

Classical liquids to be discharged:lubricating greases

Time duration for 1 complete container draining: 50 kg of grease in 30 min.

Lacquering: blue Pantone 294 c

Length of engine (mm): 225

Weight of motor (kg): 3,400

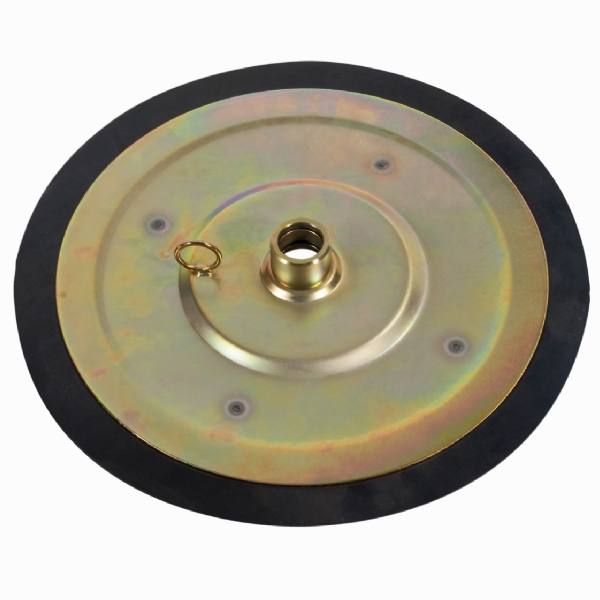

For 200-kg-container, ø 540 – 590 mm

Suction tube

Special pump mechanism

Pressure reducing valve (pre-set at 8 bar)

Male quick release adapter (20 062)

the pump is designed to be operated for discharge of lubricating and multi purpose

greases NLGI 0 up to NLGI 3 out of original manufacourer’s container, i.e. greases for recharging of centralised lubricating systems

Notes

Pump is easy to disassemble for cleaning matters.

Operate pneumatic grease pump with maintenance unit 20 218 950, only.

All Products 2 years warranty.