Electric Cable Winding and Reeling Machines

Electric Cable Winding and Reeling Machines

Electric cable winding and reeling machines are essential equipment used to ensure the organized and safe winding of cables, especially in industrial and commercial areas. When cables need to be stored properly and used for extended periods without damage, electric cable winding and reeling machines come into play. These machines play a crucial role in large workplaces, construction sites, and various production environments.

Key Features of Electric Cable Winding and Reeling Machines

-

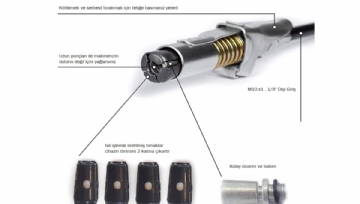

Cable Winding Mechanism: Electric cable winding and reeling machines are equipped with mechanisms that enable fast and precise winding of cables. These machines prevent the cables from tangling, ensuring their safe storage without damage. Most reeling machines wind the cable onto a reel or spool, maintaining order and making storage more efficient.

-

Compatibility with Different Cable Types: These machines can work with cables of various thicknesses and lengths. Whether it's thin telephone wires or thick power cables, these machines can wind and reel them securely. Depending on the model, machines may be designed to accommodate cables of different sizes, with adjustable winding speeds for different requirements.

-

Manual and Electric Options: Electric cable winding and reeling machines are available in both manual and electric models. Manual machines tend to be smaller and portable, while electric models are preferred for larger, more intensive uses. Electric models automate the winding process, making it faster and more efficient.

-

Durable and Safe Construction: Cable winding and reeling machines are typically made from durable metal or plastic materials, ensuring longevity and safe use. Additionally, some models include safety features that prevent overloading or damage to the cables during the winding process.

Advantages of Electric Cable Winding and Reeling Machines

-

A More Organized and Neat Work Environment: Electric cable winding and reeling machines prevent cables from tangling, resulting in a more organized and tidy workspace. This is especially beneficial in large spaces with numerous cables, as it helps save space and eliminates clutter.

-

Time Savings: Manual cable winding can be a time-consuming and labor-intensive task. Electric winding and reeling machines complete the process much more quickly and efficiently, saving both time and labor.

-

Increased Cable Lifespan: Cables that are improperly wound can suffer from bending or fraying. These machines ensure that cables are wound neatly, reducing the risk of damage and extending the life of the cables, ultimately reducing costs over time.

-

Portability and Easy Storage: Electric cable winding and reeling machines are compact, making them easy to transport and store. Many models come with handles or foldable designs, enhancing their user-friendliness and portability.

-

Safety: Properly wound cables are much safer to handle and store. Tangled or disorganized cables pose a risk in the workplace, so using winding and reeling machines significantly reduces safety hazards and creates a more secure environment.

Applications of Electric Cable Winding and Reeling Machines

-

Construction and Building Sites: Electric cable winding and reeling machines are particularly useful in large construction sites, where long power cables need to be stored properly. These machines help keep cables organized, reducing the risk of tangling and damage during use and storage.

-

Commercial and Industrial Use: In industrial settings, it is crucial to store electrical cables properly. These machines ensure that cables are wound neatly and can be safely stored for long periods, which is essential for large-scale operations.

-

Automotive and Electronics Industries: Electric cables are frequently used in the automotive and electronics sectors. Properly winding these cables is vital for both product safety and cable functionality, making these machines indispensable in these industries.

-

Events and Audio Systems: For large-scale events, such as concerts and conferences, the cables used for sound and lighting systems can become tangled and difficult to manage. Electric cable winding and reeling machines provide an efficient solution for quickly winding and storing cables during and after the event.

Conclusion

Electric cable winding and reeling machines are essential for ensuring the proper storage of cables, enhancing both workplace safety and efficiency. These machines are available in various models, catering to different needs and providing solutions for a wide range of industries. With both manual and electric options available, these machines are adaptable to businesses and users of all sizes. By using electric cable winding and reeling machines, companies can eliminate clutter, extend cable lifespan, and improve safety, making them a valuable tool in any work environment.

OTHER BLOG POSTS