Locking Automatic Grease Nipples

Locking Automatic Grease Nipples

What is a Locking Automatic Grease Nipple?

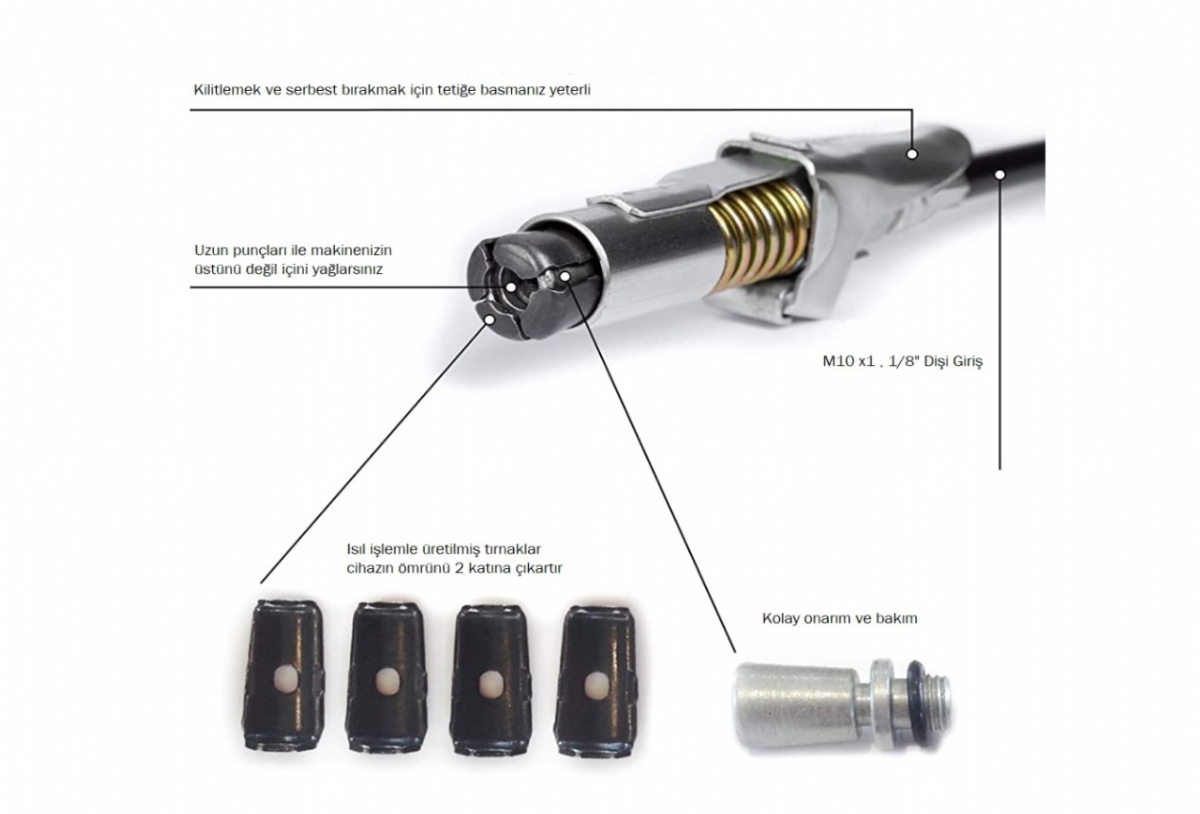

A locking automatic grease nipple is a component used in automatic lubrication systems, commonly found in industrial machinery and vehicles. These nipples ensure that grease is delivered to specific points in a machine automatically. The locking feature in the nipple’s design ensures secure installation, while the locking mechanism prevents the nipple from detaching during operation. This combination guarantees that the nipple remains in place and the lubrication process proceeds smoothly without leaks or slippage.

Locking automatic grease nipples are typically made from durable metals are designed to withstand the rigors of industrial environments. The locking mechanism allows for easy installation and removal, while the nipple delivers grease to the machine parts in need of lubrication at regular intervals.

Structure and Operating Principle of Locking Automatic Grease Nipples

Locking automatic grease nipples consist of a sturdy design with a locking and mandrel mechanism. The mandrel ensures the secure attachment of the nipple to the lubrication system, while the locking mechanism prevents the nipple from becoming detached. Grease is delivered to the lubrication points via the automatic lubrication system, where pressurized grease is distributed to areas requiring lubrication.

This design ensures that grease is applied correctly and uniformly to the moving parts of machines, reducing wear and tear and ensuring optimal performance. The locking feature allows for easy mounting and secure placement, even in environments where vibrations or heavy use could cause regular grease nipples to become loose.

OTHER BLOG POSTS