What is the Importance of Conditioner in Pneumatic Systems?

What is the Importance of Conditioner in Pneumatic Systems?

Importance of Air Regulator in Pneumatic Systems

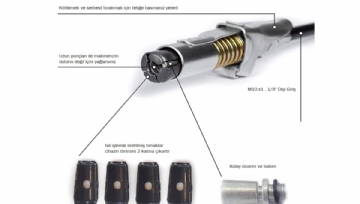

Air regulators are the fasteners that take important roles by keeping the water in the air and protecting your equipment against rusting and corrosion. Although the Air Regulator looks like a single piece of product, it consists of 4 different pneumatic parts.

Filter; It holds the dust and particles in the line.

Lubricant; It provides lubrication of your equipment in a certain period.

Pressure regulator; reduces or increases the pressure of the air coming from the system.

Manometer: allows the set pressure in the system to be displayed in

Even though there is a dryer right at the exit of your compressor, the air that circulates in the pipes in the facility causes evaporation and moist air production due to the temperature difference between the outside and the pipeline.

This evaporation and moisture can rust or corrode your lubricating equipment. Although lubrication equipment provides oil transfer, they cannot lubricate themselves. The use of an air regulator is mandatory, especially since the pneumatic motor will need regular lubrication.

The air regulator not only protects your pump from excessive pressure, but also provides dry and clean air. It also ensures regular lubrication of all your lubrication equipment. Thus, the life of your equipment is extended and it provides a safe and performance lubrication opportunity.

All grease and oil pumps are designed to operate at a maximum pressure of 8 bar. Compares your air source equipment outside the recommended pressure to costly breakdowns. Failures caused by high pressure leave your equipment out of warranty.

OTHER BLOG POSTS